Pogo Pin Manufacturers 2025–26: Global Leaders

Pogo pins remain critical in ensuring reliable electrical connections in devices across medical, automotive, and consumer electronics.

In 2025–26, demand continues to rise due to increasing miniaturization and the need for durable, spring-loaded contact interfaces.

This guide outlines the key players, industry trends, and selection factors to help procurement managers and engineers make informed decisions.

What Are Pogo Pins and Why Are They Critical in Modern Electronics?

Pogo pins, or spring-loaded connectors, consist of a plunger, barrel, and spring. Their core function is to enable a stable, repeatable connection under mechanical stress.

They are used in:

-

battery charging stations,

-

testing interfaces,

-

communication devices,

-

PCBs in IoT and wearable technology.

Unlike rigid connectors, pogo pins accommodate movement, vibration, and frequent mating cycles, making them ideal for dynamic environments.

Precision-engineered pogo pins reduce signal loss and contact resistance, directly impacting product reliability.

Miniaturization in electronics has elevated the importance of low-profile, high-performance pins. As a result, the global connector market is seeing more investment in pogo pin innovation.

Global Market Outlook for Pogo Pins: 2025–26 Trends

The pogo pin industry is forecast to grow steadily through 2026, driven by demand from electric vehicles, medical wearables, and high-frequency communication tech.

企业微信截图 17452271935306

Key trends:

-

Smaller sizes: Increased adoption in miniaturized devices.

-

Higher current ratings: Supporting fast charging and power delivery.

-

Modular designs: Custom connectors for unique use cases.

-

Environmental durability: Corrosion resistance and IP-rated sealing.

Asia-Pacific continues to dominate manufacturing, but North American and European OEMs increasingly rely on specialized suppliers for custom applications.

Sustainability is also influencing the sector—recyclable materials and RoHS/REACH compliance are now standard requirements.

Top Global Pogo Pin Manufacturers in 2025–26

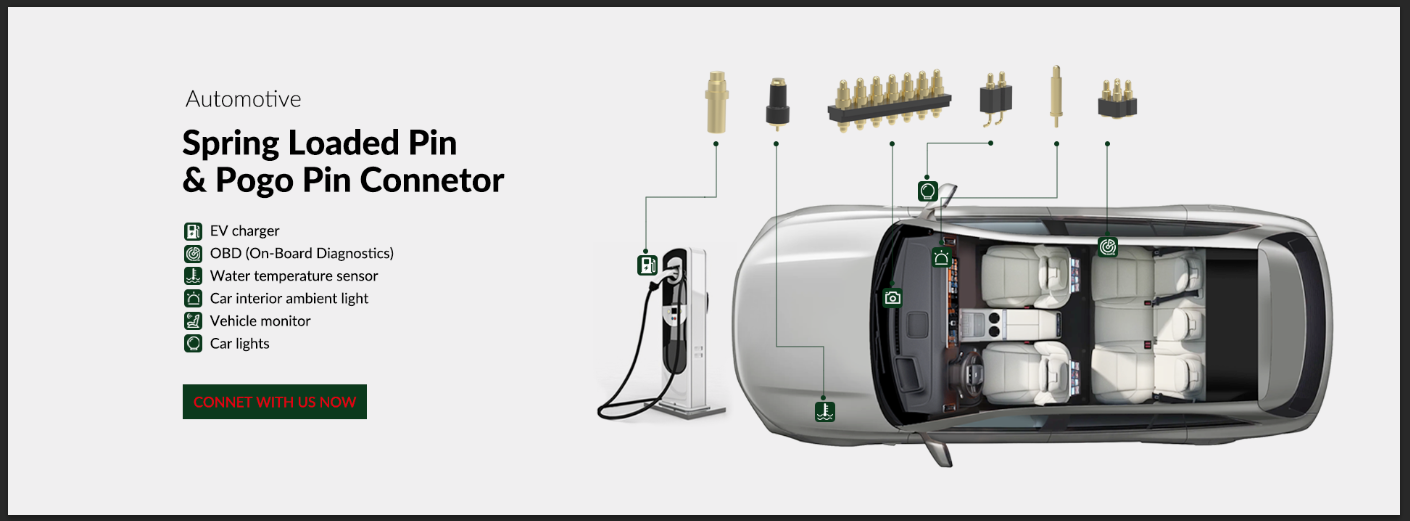

CFE Corporation – Precision and Custom Solutions

Based in China, CFE Corporation specializes in custom pogo pin designs tailored to client specifications. Their product line includes:

-

High-current pogo pins

-

Waterproof connectors (up to IP68)

-

Magnetic pogo pin connectors

CFE’s in-house R&D and manufacturing allow for rapid prototyping and volume production. They offer competitive pricing and strict quality control, meeting ISO and RoHS standards.

Their global supply reach and flexible customization make them a preferred choice for consumer electronics and electric vehicle applications.

Mill-Max – High Reliability for Harsh Environments

Headquartered in the U.S., Mill-Max is known for precision-machined interconnects. Their pogo pins are ideal for high-vibration and extreme temperature conditions.

Product strengths:

-

Gold-plated contacts

-

Custom spring force options

-

Industry-standard footprints

Mill-Max serves aerospace, defense, and industrial markets where failure is not an option. They maintain local engineering support and robust supply chains across North America.

Harwin – Compact and Durable Engineering

UK-based Harwin delivers compact pogo pin solutions focused on high-density board applications.

Their emphasis lies in:

-

Lightweight, low-profile designs

-

High mating cycle ratings

-

Shielded connector variants

Harwin’s innovative Gecko and Datamate series use pogo pin tech to reduce space without compromising reliability. Popular in wearables, drones, and small-scale robotics.

Others to Watch in the Industry

Other notable pogo pin suppliers making strides:

-

Yokowo Co., Ltd. (Japan): Medical-grade connectors

-

QA Technology (USA): Advanced test probe systems

-

Preci-Dip (Switzerland): Swiss-made micro connectors

Each contributes specialized technologies suited to unique industries or environments.

Factors to Consider When Choosing a Pogo Pin Supplier

When sourcing pogo pins, consider:

-

Electrical performance: Current capacity, contact resistance

-

Mechanical durability: Mating cycles, spring force tolerance

-

Material quality: Gold plating, anti-corrosion finishes

-

Customization: Availability of tailored design solutions

-

Certifications: ISO, RoHS, UL compliance

-

Lead times: Production and delivery capabilities

Working with a manufacturer offering in-house tooling and rapid prototyping reduces project timelines and risks.

Applications Across Industries: Where Pogo Pins Excel

Pogo pins are essential in high-cycle, compact environments across various industries:

-

Consumer Electronics: Charging docks, smartphones, smartwatches

-

Automotive: Sensor modules, EV battery interfaces

-

Medical Devices: Diagnostic instruments, wearable monitors

-

Telecom: RF signal transfer, test, and measurement tools

-

Industrial Automation: Test fixtures, robotic end-effectors

Their resilience and adaptability make them a universal component for secure electrical contact under mechanical strain.

Final Thoughts: Staying Ahead in a High-Demand Connector Market

With increasing miniaturization and high-reliability requirements, pogo pins will play a pivotal role in next-gen electronic systems.

Choosing the right manufacturer ensures product longevity, safety, and cost-efficiency.

For those seeking custom, high-quality pogo pin solutions in 2025–26, partnering with established global leaders like CFE Corporation offers both performance and peace of mind.